Are you prepared to transform your recycling operations and minimize your environmental footprint? Initiating a quote request for one of our PolyWiz machines is your initial stride toward attaining sustainable and cost-effective solutions.

Welcome to PolyWiz

The Next Generation of Styrofoam Recycling Equipment

Turning Foam Waste Into Eco-Friendly Solutions

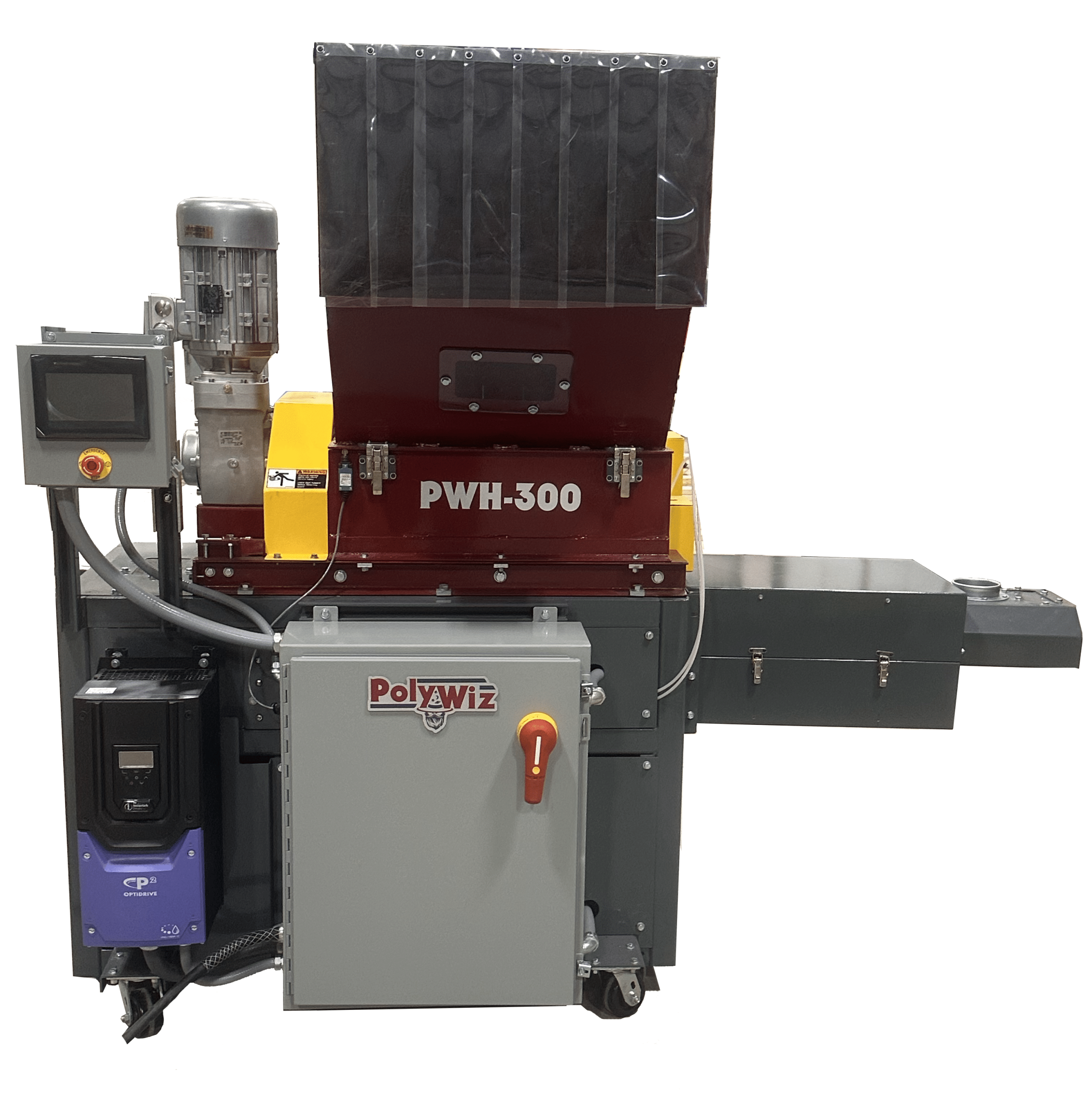

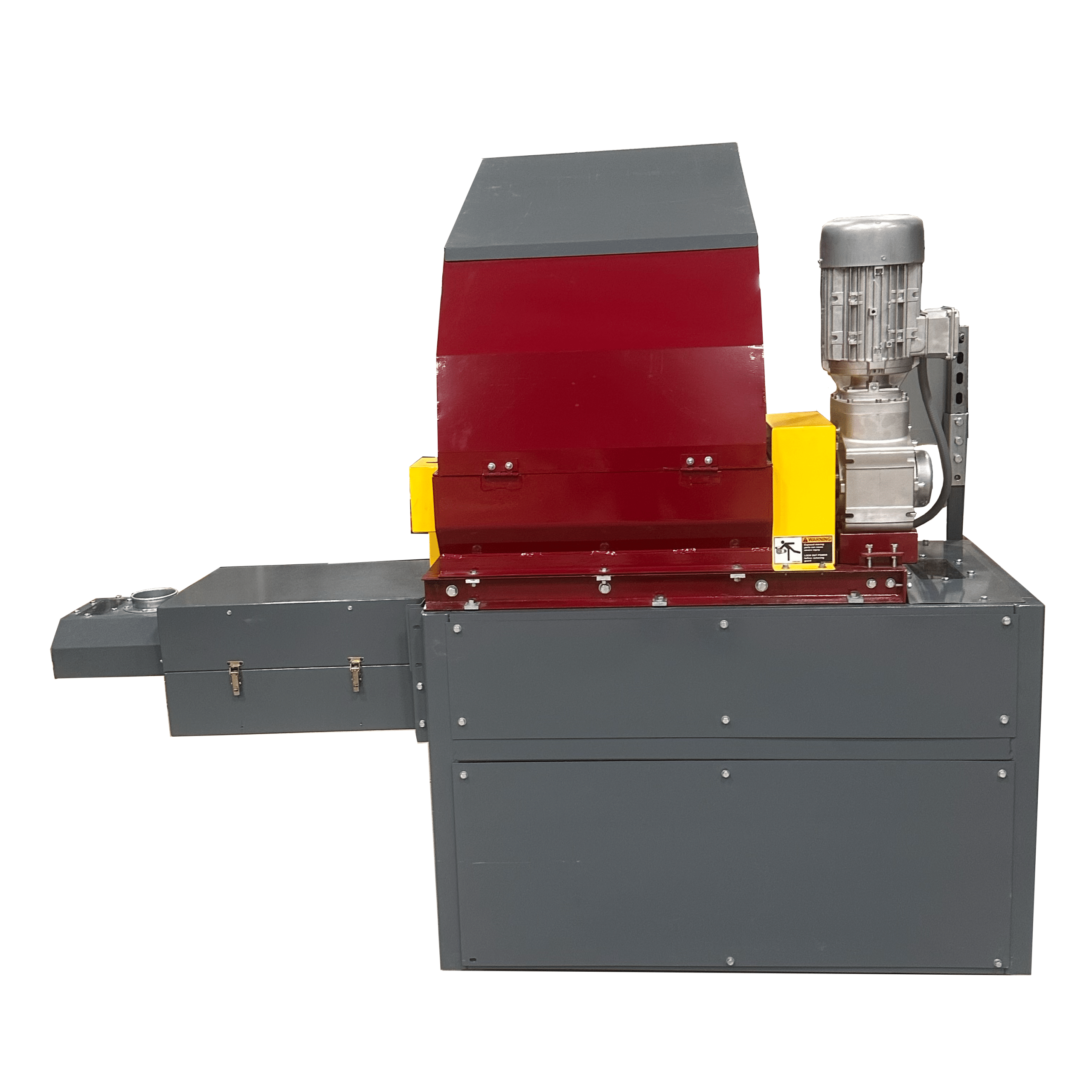

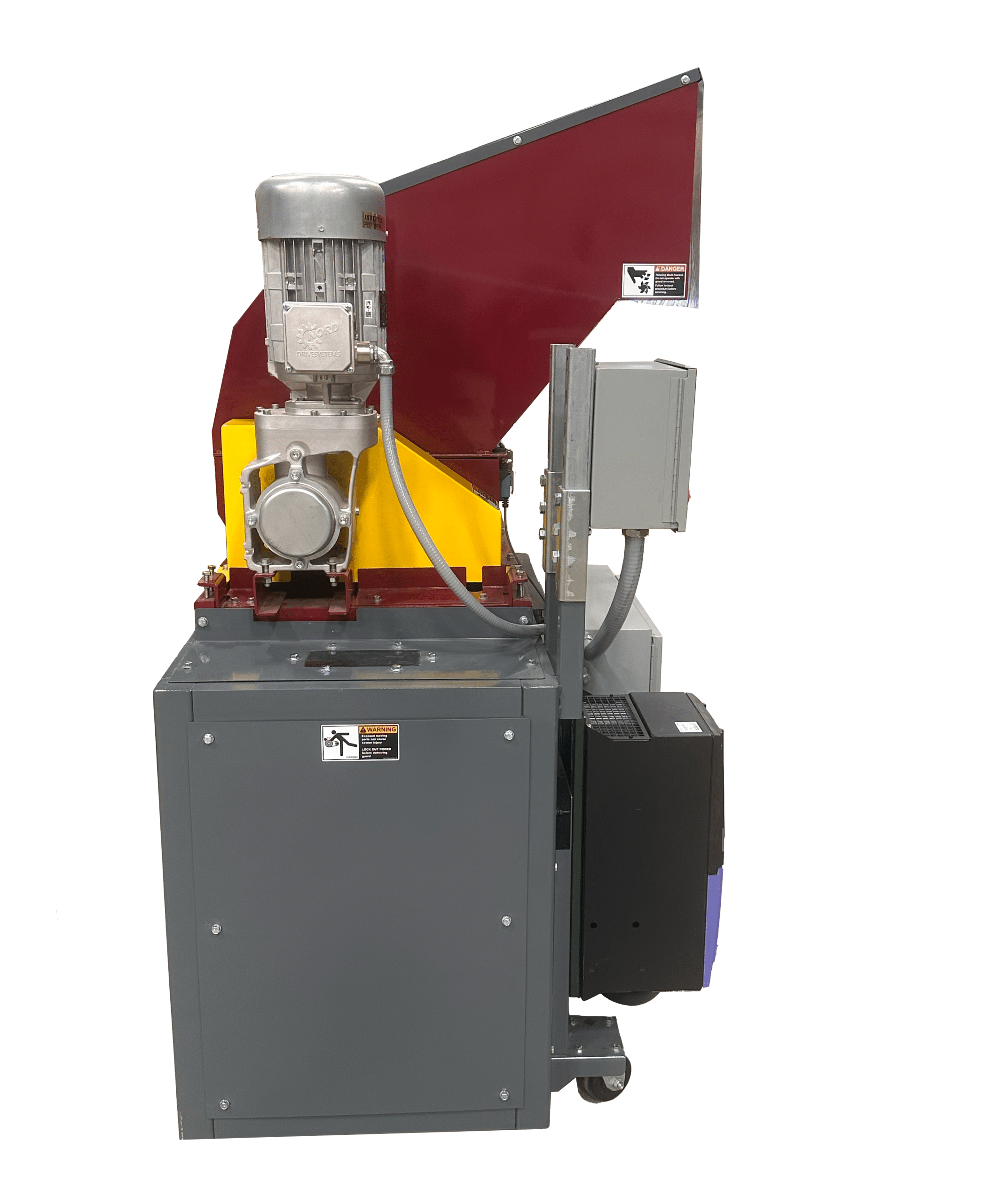

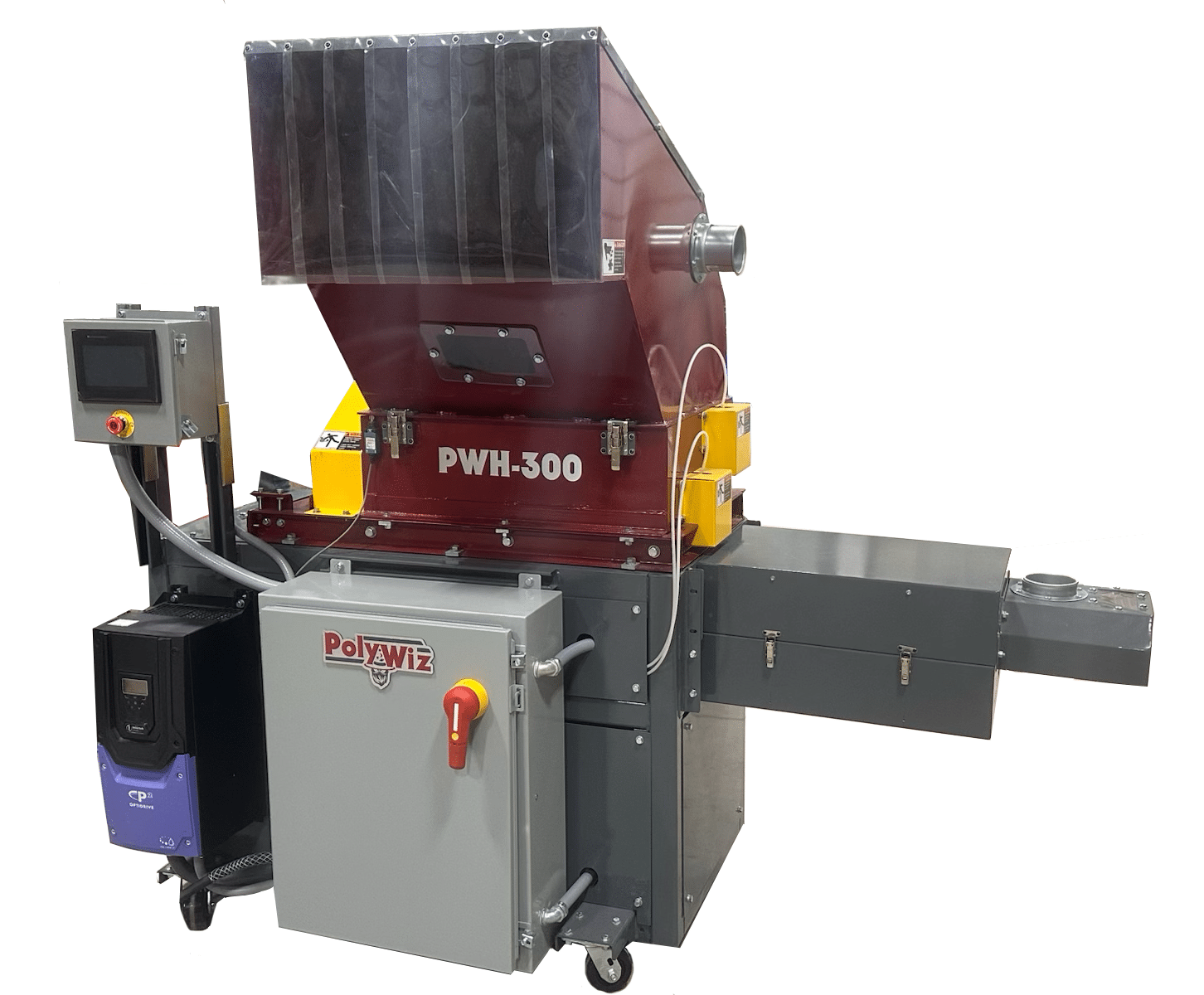

PWH-300 Heavy Duty Thermal Styrofoam Densifier

The PWH-300 stands as one of our flagship and highly sought-after densifiers. This hand-fed machine efficiently processes foam by shredding it, simultaneously applying heat to densify and extrude purge blocks, resulting in the production of recyclable final products. Capable of densifying expanded polystyrene (EPS), expanded polyethylene (EPE), and expanded polypropylene (EPP), the PWH-300 offers versatility in waste management solutions.

Get a Quote Download Our Flyer Machine DrawingSpecifications

| Shredder Motor HP | 5 hp |

|---|---|

| Auger Motor HP | 15 hp |

| Voltage | Three Phase 208V/230V/460V |

| Weight | 2,300 lbs |

| Throughput | Up to 300 lbs/hr |

| Infeed Type | Manual Feed |

| Infeed Dimensions | 27.5″ x 14.5″ |

| Machine Dimensions | 39″ x 89″ x 77″ |

| Materials Processed | EPS, EPE, EPP |

| Volume Reduction Ratio | 90:1 |

| Available Options | Exhaust Vent Kit, Form Molds |

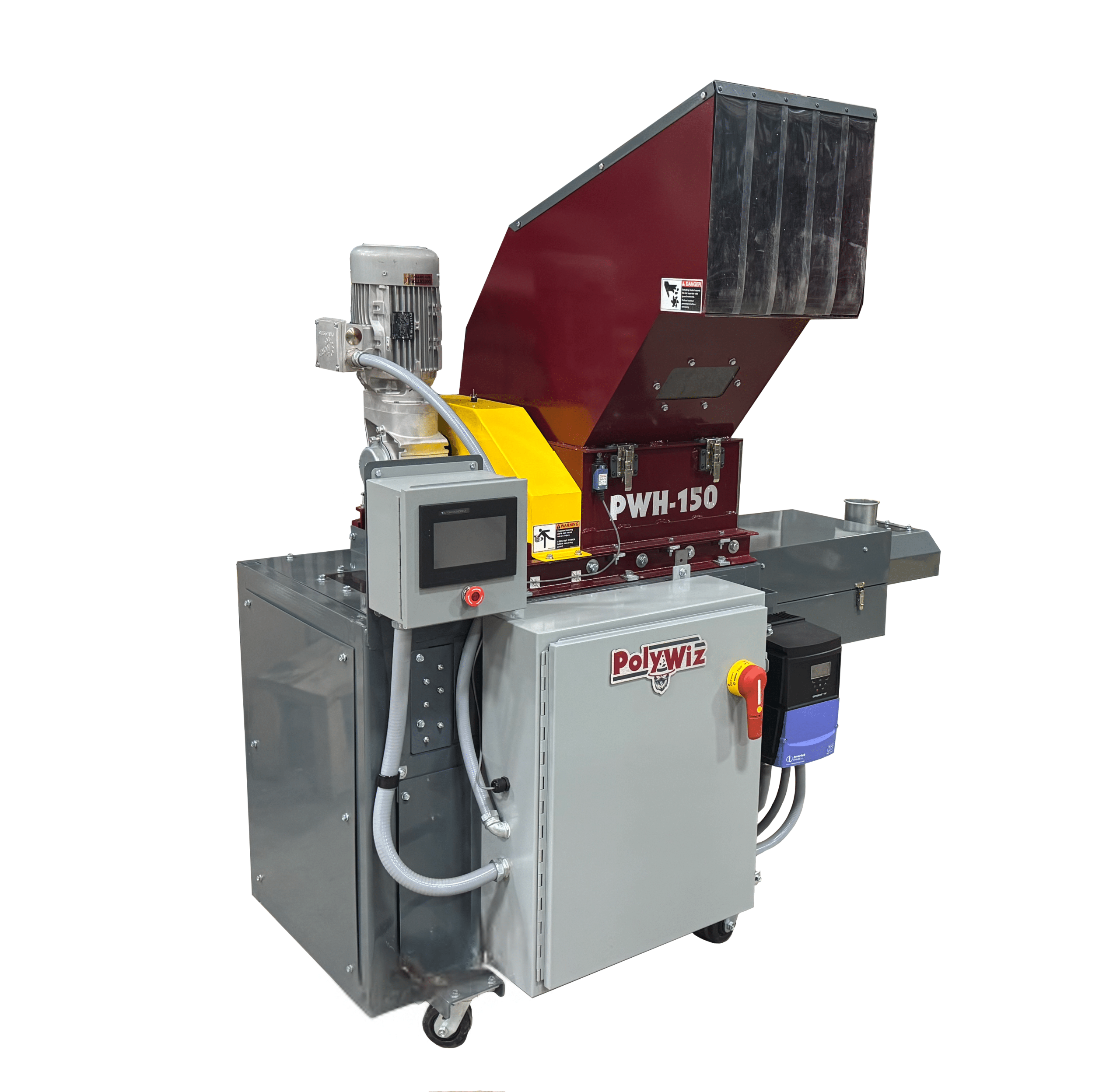

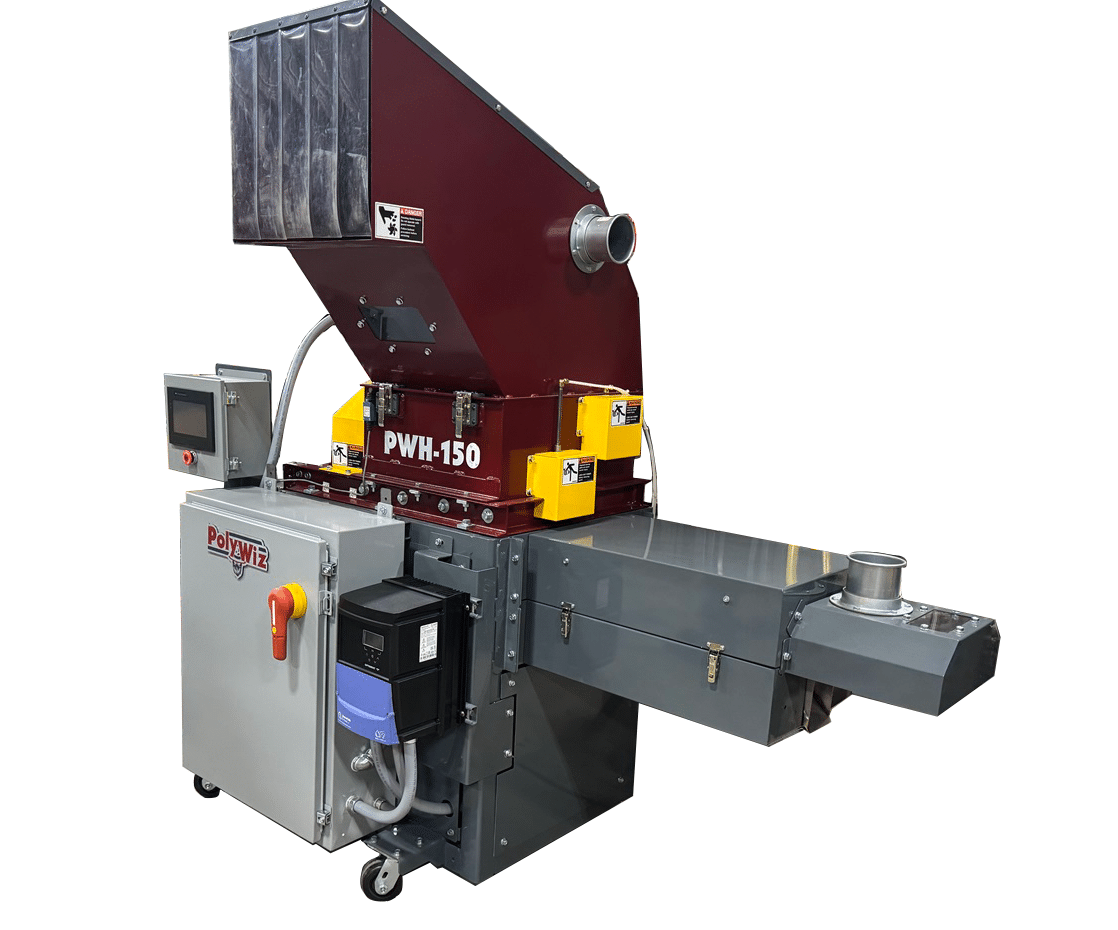

PWH-150 Light Duty Thermal Styrofoam Densifier

The PWH-150 is a hand-fed machine that reduces foam volume at a 90:1 ratio through a process of shredding while adding heat to densify and extrude purge blocks. The PWH-150 is capable of processing up to 150 lbs./hour of EPS (expanded polystyrene), EPE (expanded polyethylene), and EPP (expanded polypropylene) foam.

Get a Quote Download Our Flyer Machine DrawingSpecifications

| Shredder Motor HP | 3 hp |

|---|---|

| Auger Motor HP | 5 hp |

| Voltage | Three Phase 208V/230V/460V |

| Weight | 1900 lbs |

| Throughput | Up to 150 lbs/hr |

| Infeed Type | Manual Feed |

| Infeed Dimensions | 17.5″ x 14.5″ |

| Machine Dimensions | 39″ x 79″ x 77″ |

| Materials Processed | EPS, EPE, EPP |

| Volume Reduction Ratio | 90:1 |

| Available Options | Exhaust Vent Kit, Form Molds |

Made in America

Our unwavering commitment to excellence and dependability is evident in our choice to produce all our machines in the USA. Opting for local manufacturing underscores our emphasis on quality control while reaffirming our dedication to bolstering the American economy and workforce. This decision enables us to meticulously oversee each stage of production, from procuring top-notch materials to implementing stringent quality assurance protocols.

Turn Your Foam Waste Into Cash

Densifying foam waste minimizes and, in most cases, eliminates haul-away fees significantly reducing costs for businesses. In addition, the densified foam has value and can be reused to make things like picture frames, furniture, toys and park benches. The combination of haul-away savings and the value of the densified product typically results in a return on investment in 12-18 months!

- Turn Your Waste Into a Sellable Product

- Return on Investment in 12-18 Months

- Eliminate Haul-Away Fees

Why Choose PolyWiz?

American-Made Machinery

Our dedication to quality and reliability shines through our decision to manufacture all our machines domestically in the USA.

One-Year Warranty on All Parts and Labor

We are confident in the quality and durability of our products, which is why we offer a comprehensive one-year warranty covering all parts and labor, ensuring your peace of mind and satisfaction.

Save Money and the Planet

Our cost-effective densifiers transform waste management practices, substantially decreasing the amount of materials sent to landfills.

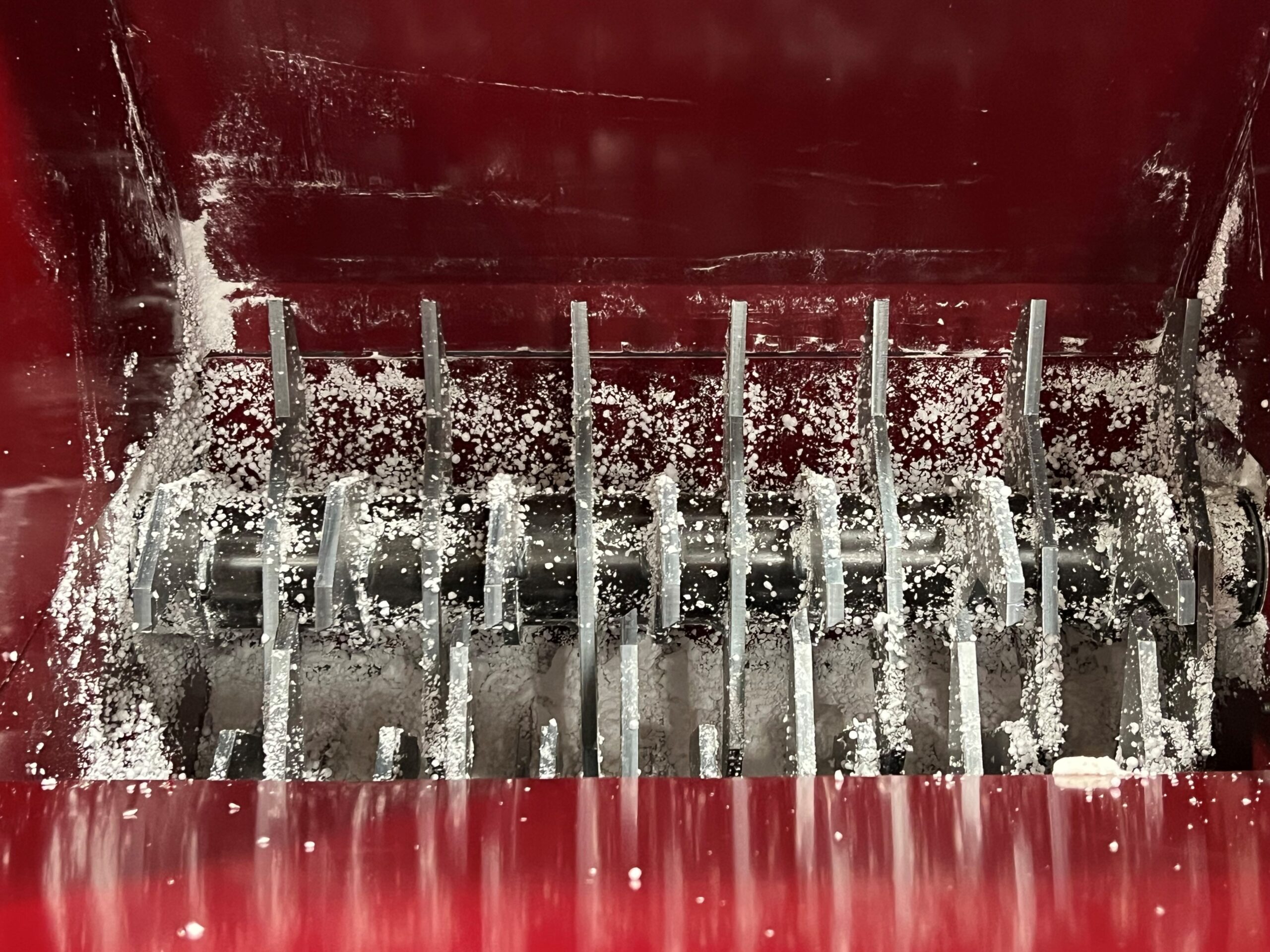

Our Thermal Densifier in Action

View the video above to witness our thermal densifier in operation! As the styrofoam is introduced into the hopper, it undergoes shredding, melting, and is eventually extruded into the purge mold, where it solidifies into a compact block.

Request a Quote Today

PolyWiz enables businesses to embrace eco-friendly practices, leading to both cost savings and environmental advantages. By selecting our solutions, businesses not only enhance their financial performance but also contribute significantly to the preservation of our planet’s health. We welcome you to join us in advancing towards a sustainable future.

Call Now: 1-888-350-2079Simple Operation

-

Setting Temperature: Initiate by adjusting the desired operating temperature using the control panel of the densifier. The appropriate temperature setting varies depending on the type of the foam being processed.

-

Heating Process: Allow the system time to heat up to the designated temperature.

-

Auger Activation: Once the system reaches the specified temperature, the auger will automatically commence operation. This component ensures a consistent material flow for processing.

-

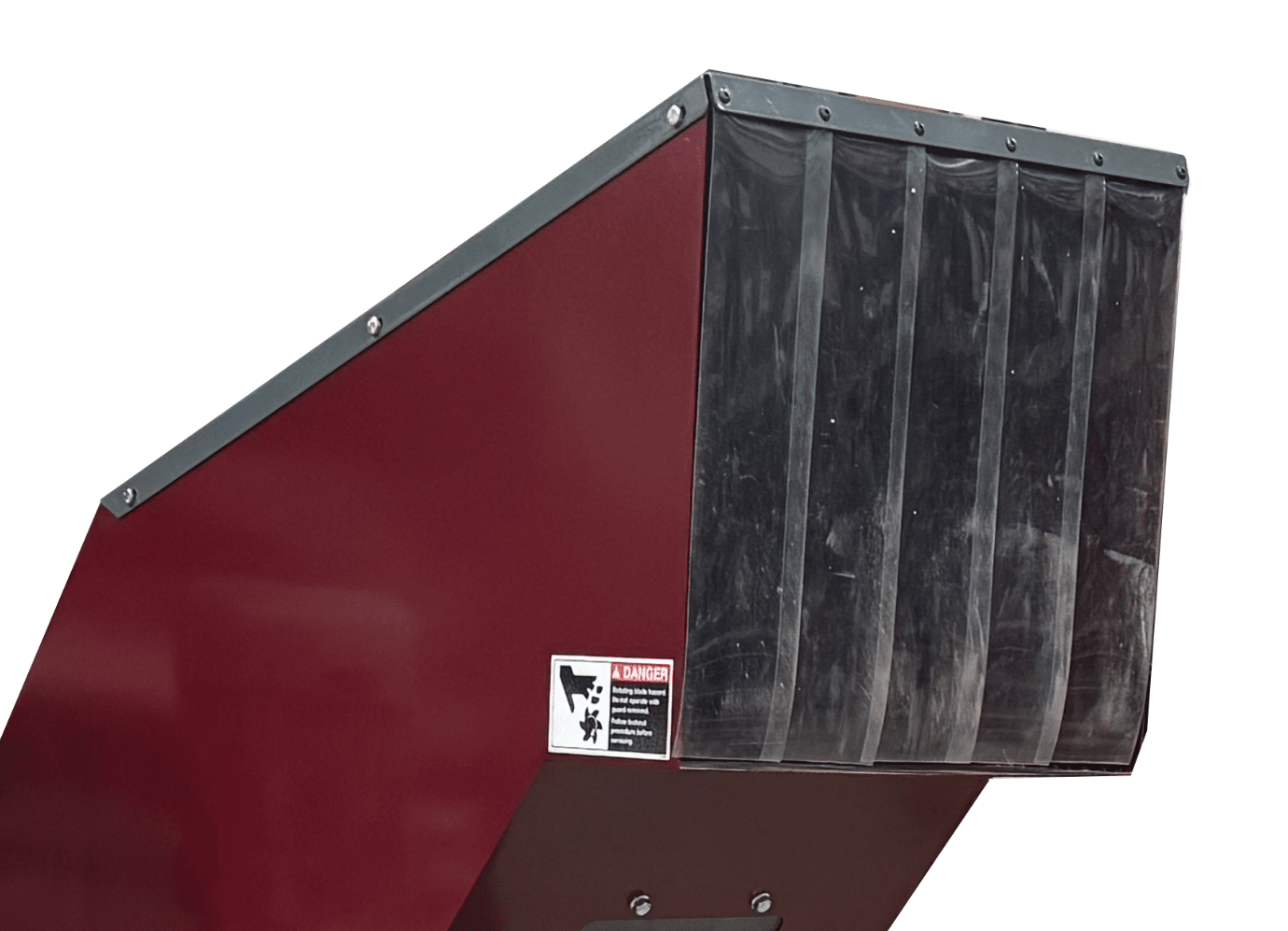

Shredder Activation: Following the activation of the auger, the shredder component of the densifier will engage. Responsible for breaking down larger styrofoam pieces into smaller, more manageable pieces, the shredder prepares the material for densification.

-

Ready for Operation: With both the auger and shredder now operational, the PolyWiz Thermal Styrofoam Densifier is primed for use. You can begin feeding Styrofoam waste into the hopper, initiating the processing phase.

- System Shutdown: Simply push the system stop button. The shredder will stop followed by the auger and heat.

Simplified System Maintenance

Positioned strategically on a singular, user-friendly panel, all grease fittings ensure lubrication tasks are both effortless and convenient. This arrangement not only simplifies maintenance procedures but also motivates operators to adhere to routine upkeep schedules. By streamlining maintenance protocols and offering easy access to crucial components, we empower our clients to maintain the longevity and efficiency of their equipment, ultimately enhancing productivity and minimizing downtime.

- Easy to access grease fittings all in one convenient location

- Easy to remove guard to access drive chain and apply lubricant

- Easy to locate hole for simple gear oil application

- And that’s it! Machine maintenance is simple with PolyWiz!

Feeding the Machine

Our thermal densifiers come equipped with a manual feeding system, providing operators with complete control over the input process. This manual feeding mechanism enables operators to closely monitor and adjust the rate at which foam waste is fed into the densifier. This hands-on approach offers flexibility in handling different types of foam materials, ensuring efficient processing while reducing the risk of jams or overloading.

What Materials Can it Densify?

- Expanded Polystyrene (EPS)

- Expanded Polyethylene (EPE)

- Expanded Polypropylene (EPP)

Densifier Breakdown

Powder Coated Finish

Powder coating offers exceptional corrosion resistance compared to traditional paint, significantly prolonging the lifespan of our equipment.

Simplified Maintenance

Regular maintenance prolongs machinery lifespan and is more likely to be performed when it’s straightforward. Conveniently, all grease fittings are positioned on a single, easily accessible panel.

Powerful Shredder

Our machines are equipped with a robust shredder that effectively transforms larger foam pieces into smaller, more manageable fragments, facilitating the densification process with efficiency.

Purge Mold

The purpose of the purge molds is to shape the extruded melted product into blocks, which can be conveniently stacked on a pallet for efficient shipping to your recycler.

Touchscreen Interface

Touchscreen interfaces streamline equipment operation, minimizing the likelihood of operator errors.

Temperature Control

This feature enables users to finely tune the operating temperature to match the precise requirements of the material undergoing processing.

Heavy Duty Casters

Heavy-duty casters offer superior mobility in contrast to standard rail mounts.

Contact the Experts

We are dedicated to offering comprehensive support, ensuring that all your questions and concerns are met with expert guidance. Whether you require detailed product specifications, assistance with installation, or simply wish to explore our sustainable solutions further, our team is committed to assisting you through every step of the process.

Turning Foam Waste Into Eco-Friendly Solutions

Turning Foam Waste Into Eco-Friendly Solutions